Are you developing a new packaging concept and would like to know which is the most suitable sterilization type? Or would you simply like an overview of the various types of sterilization? Below you will find an overview of gamma, x-ray and steam sterilization at Früh Verpackungstechnik AG.

Gamma sterilization

More than 40% of all medical products marked «sterile» involve the use of gamma irradiation. With this process, the gamma irradiation is released from the enriched cobalt-60 isotope. During beta decay, unstable cobalt-60 is converted into an excited state of nickel-60 and is then changed into stable nickel-60 through the emission of two gamma rays of 1.17 and 1.33 mega-electron volts. The half-life of this decay cascade is 5.27 years, making it the longest-lasting of all unstable cobalt isotopes.

Because of its characteristics, the gamma quanta can be described as both particles and as waves. This quality allows the gamma irradiation to penetrate deeply into the materials, which in turn makes it very well suited for treating medical products on, for example, EU pallets.

In most cases, medical products are treated to reduce and kill microorganisms, such as bacteria, that are on the products being treated. Medical products are said to be sterilized when the treatment process meets the requirements of EN 556-1. The procedure for sterilizing medical products using gamma irradiation is describe in standards series EN ISO 11137.

X-ray sterilization

Since the beginning of the 21st century, the market for medical products has seen another very effective sterilization type, so-called x-ray irradiation. As the name implies, this involves the use of x-rays or bremsstrahlung. The characteristics of this type of irradiation are very similar to gamma irradiation, but with the major difference that x-rays can be created artificially using electron acceleration and abrupt braking. With the help of a powerful electron accelerator of up to 7 MeV, electrons are accelerated to nearly light speed and shot at a target. In addition to a large amount of heat, the abrupt braking of the electrons also releases x-rays. These are then used, like gamma quanta, to treat medical products, for example, on EU pallets.

It can be said that x-rays penetrate materials better than gamma rays. This is because of the spectrum of rays that are produced, which will not be explained in further detail here. In terms of standards, there is no difference between the sterilization of medical products using gamma or x-ray irradiation

Steam sterilization

Steam sterilization is one of the oldest types of sterilization and is based on the principle of killing viable organisms and cells using heat. This results in the denaturation of proteins and the interruption of essential cell processes, which in turn leads to the death of microorganisms and viable cells.

In addition to medical products, a number of pharmaceutical products are treated using steam sterilization to reduce and kill microorganisms and other harmful organisms.

Tailored to the large range of products, there are a number of different processes available. These can be roughly divided into hot air sterilization and steam sterilization. Steam sterilization will be described in more detail here. In this process, the feed water, following the steam saturation curve, is heated in a steam sterilizer using a steam generator and released into the sterilization chamber as saturated steam. The chamber must first be emptied of air (evacuated) so the steam can reach the products to be sterilized without hindrance. Any remaining air would function as insulation during the steam sterilization and the steam might not be able to transfer all of its energy to the goods being sterilized. In addition, care needs to be taken that suitable packaging materials are used during steam sterilization through which the steam can pass and end up on the product being sterilized. In many cases, a fractionated pre-vacuum process is used for the sterilization of medical products, with a final vacuum drying process (FRVV-VMT, or fractionated pre-vacuum process – vacuum with drying). However, the process can also be adjusted in a modular manner depending on the product or process specification. Standards series DIN 58950 provides further details (pharmaceutical sterilization products) about the individual processes using heat and steam.

Material suitability - which type of sterilization is the right one?

In general, the same materials are suitable for irradiation using gamma rays and x-rays, as both of these sterilization types involve electromagnetic irradiation that have an ionizing effect on the irradiated material through the interaction of photons and electrons An overview of suitable materials for gamma ray, x-ray and steam sterilization can be found in AAMI TIR17:2017.

Please note that the use of x-rays, which are created through the acceleration of electrons using more than 5 mega-electron volts of energy, requires a material activation test. This requirement is defined in EN ISO 11137-1.

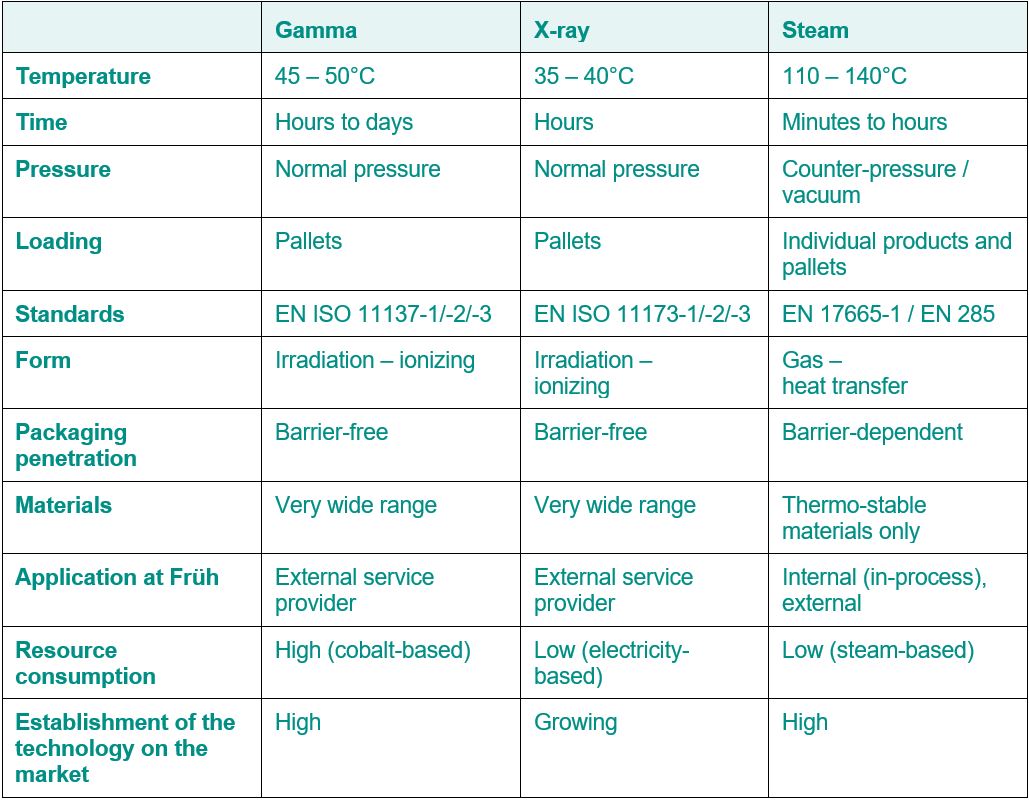

Comparison of the types of sterilization

- Category:

- Year:

- 2021